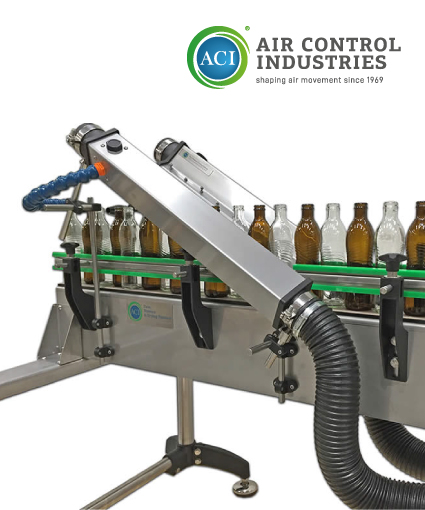

Application

The DRI-Line Series can be used for the following applications:

- After filling, washing or rinsing

- Prior to ink jet coding

- Prior to packaging

- Prior to labelling

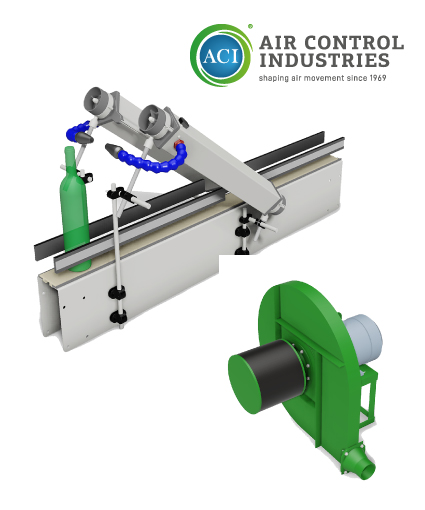

Compared to compressed air nozzle systems, the DRI-Line blower-driven series:

- Reduces high energy consumption - operation running costs reduced by as much as 90% - blower driven air from an advanced ACI air knife uses far less energy because it produces higher volumes of low-pressure air (clean, safe air) - by comparison, compressed air energy costs are very high; by switching from compressed air to blower-driven air payback can be achieved in as little as a few months

- Reduce high noise levels - lower air pressures reduce the expansion ratio and turbulence of the air produced

- Is cleaner - blower-driven air is both dry and oil-free; no expensive additional air filtration is required

The CB-B is suitable for standard shaped cylindrical glass & PET bottles of most bottle sizes; for non-standard bottle shapes, please discuss this with us.