The DRI-Line Series range of air knife drying systems are primarily focused on removing surface moisture in the packaging process to help improve the quality of date coding and labelling processes, and are produced by ACI (Air Control Industrustries), who have been engineering systems for the packaging industry for over 50 years. They are typically installed in-line to the outfeed of automatic filling systems which may have integral an external rinse function, but don't have drier functionality.

The benefits of the DRI-Line Series include:

- Helping to increase the speed of processing and packaging output

- Eliminating the smearing of labels and date codes

- Preventing the misapplication of tamper-proof labels or bands

- Helps remove threat of stress corrosion

- Stops watermarks from forming on the bottom of cans

- Compared to compared air nozzle systems, the DRI-Line Series offers the following reductions: energy consumption; noise levels; maintenance - see Application

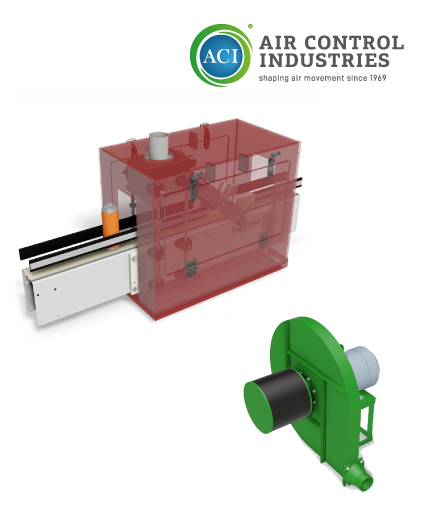

The CB-C Craft Can Drying System is specifically designed to surface dry aluminium cans for date coding, labelling or packaging. Using a small centrifugal blower, ACI’s ‘CB-C’ system is suitable for line speeds up to 6,000 cans per hour. The system is designed to be easily operated and maintained.

- Speeds of up to 6,000 cans per hour

- Capable of drying 330ml through to 568ml cans, giving a 98%* residual of water. [(*) figure attained after rigorous product testing at ACI’s test facility in Axminster.]

- 5.5kW centrifugal radial bladed blower - drys can tops, bottoms & sides

- 24 month ACI warranty

- Available with or without spray enclosure and drip tray

These machines can be linked in-line to canning lines which don't have a drying facility, date coders and labelling machines

Installed & commissionined by our Engineers.

Please call us on 01404 892100 to discuss these machines.

Please see the Drying Systems category in Catalogue for our full range of drying machines.

Please see Canning Lines and Labelling machines for our full range of canning & labelling equipment.

[Did you know that our sister company, Rawlings, supplies bottles? See Glass Packaging]