Features

The Willmes Pressing Principle

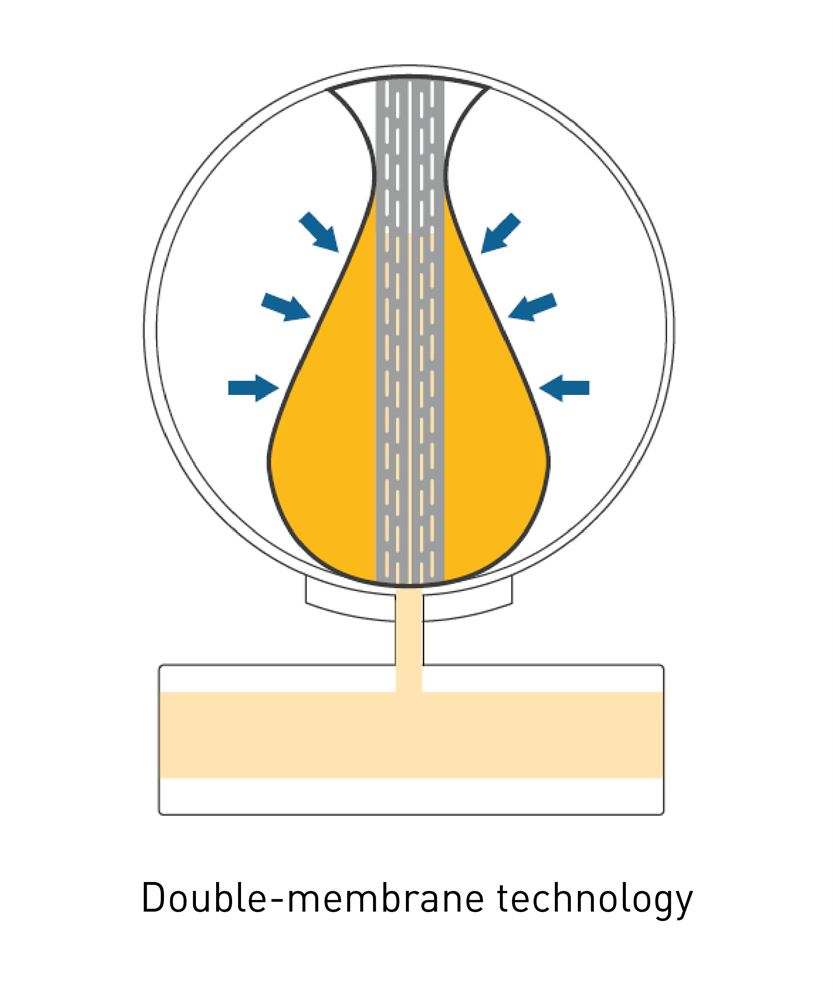

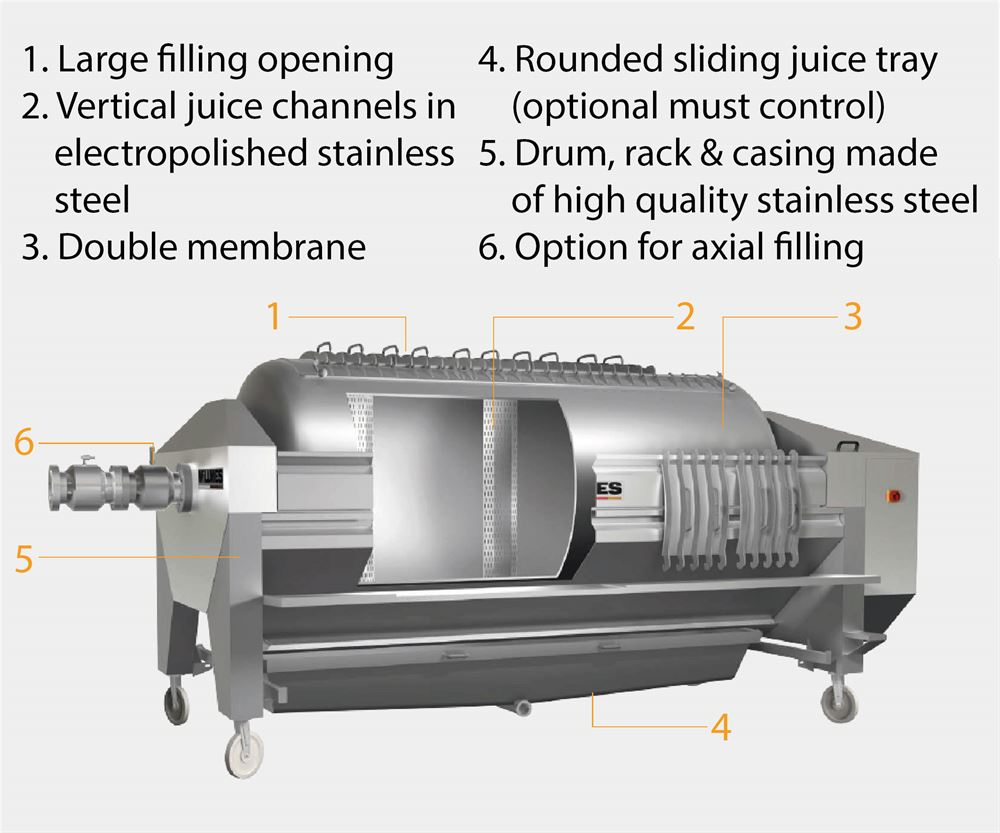

- Double membrane technology:In contrast to a half-sided membrane, the double-sided membrane has a substantially larger (double) area of pressure application. In terms of physics, this means less pressure expenditure and less compression of the material to be pressed at the same force, which acts uniformly from all sides on the material to be pressed.

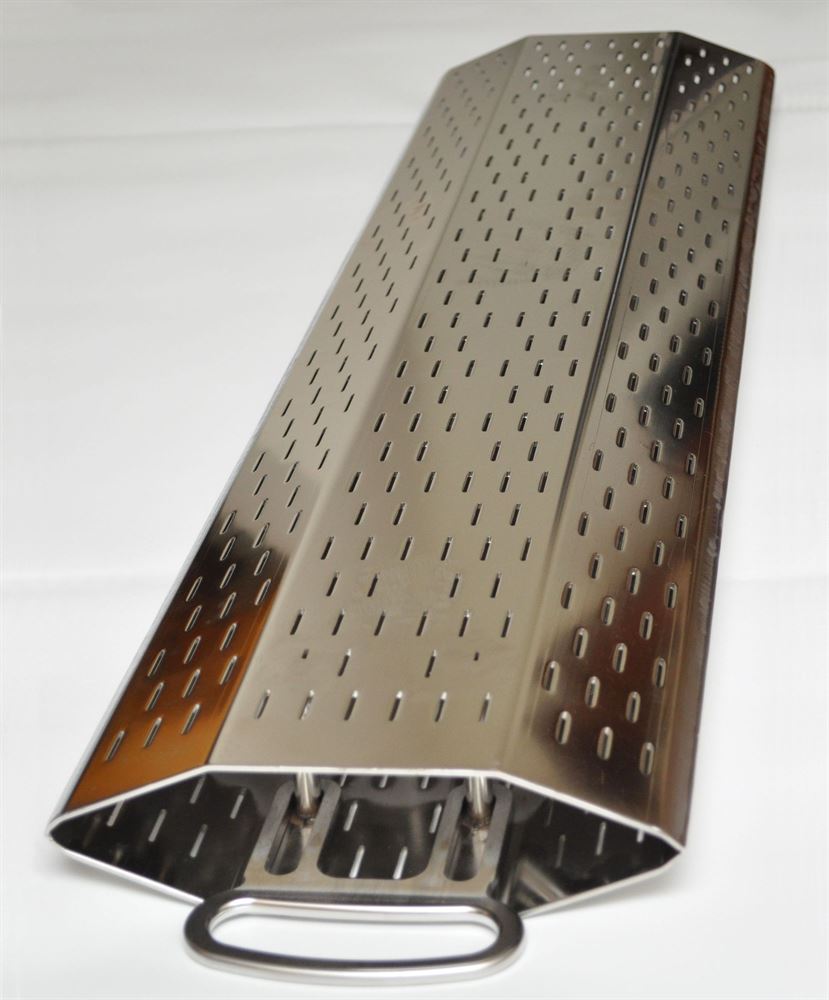

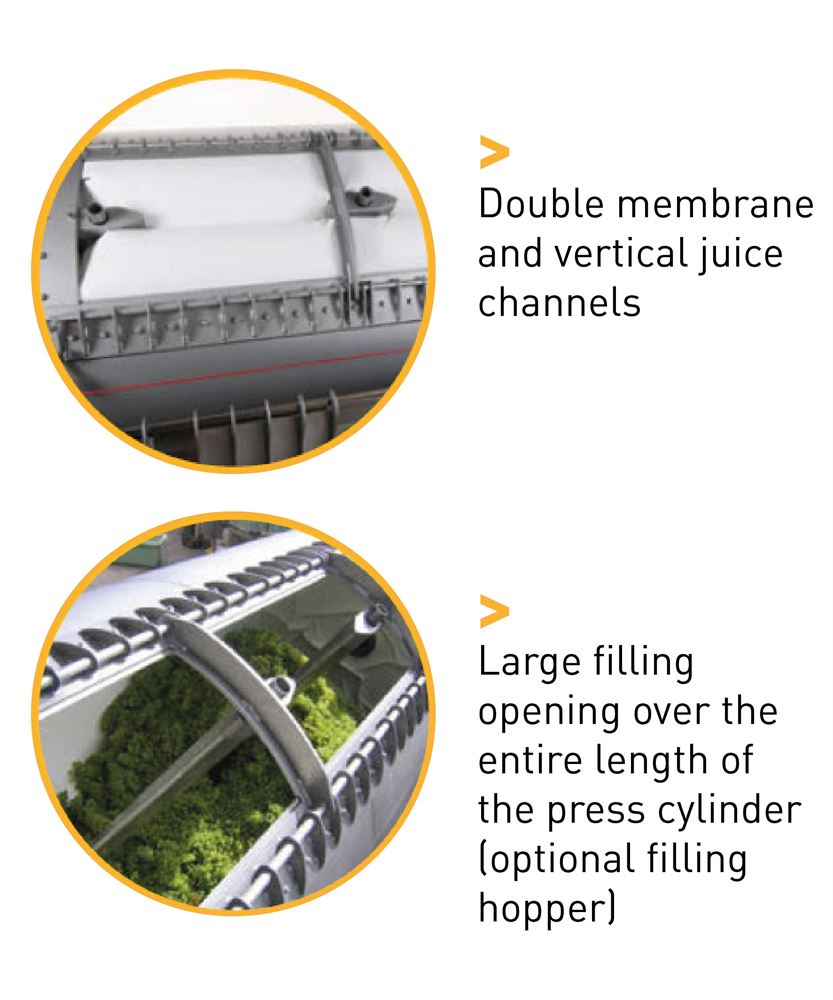

- Vertical juice channels: The double-sided membrane presses the material to be pressed against the vertical electropolished juice discharge areas, which act like natural drains. Irrespective of the filling height, this always results in the same short juice paths, which allows the juice to drain more directly and quickly. If the membrane is relieved of pressure (vacuum released), the material to be pressed falls together. This makes the rotational effort for crumbling negligible and fewer pressing cycles are required. The mechanical load on the material to be pressed is kept to a minimum; therefore, there are less lees and a higher yield of juice of premium quality. *Other features include:

Other features include...

- Intelligent pressing programs, which are perfectly adapted to all grades and types of grape harvest for optimum pressing results

- Easy and intuitive operation via touch-screen

- Large filling opening over the whole length of press tank to simplify and accelerate the filling/emptying process (filling hopper with lifting shoes optional)

- Unique filling opening ensures optimum distribution of the material to be pressed, while dispensing with all rotations for enhancing distribution

- The vertical juice channels can be be dismantled in a few simple steps for easy cleaning

- Corner and edge-free press body for minimal dirt traps and reduction in cleaning times

- Pneumatic control with reversible blower for an efficient and energy-saving pre-pressure and evacuation control (integrated compressor optional)

- Round-shaped, sliding juice tray (must pump control optional)

Specification

Approximate pressing times:

- Whole cluster: 2.5 hours

- Fresh grapes: 2 hours

- Fermented grapes: 1.5 hours

Merlin PLUS+ 1200 model

- Maximum weight

- Whole cluster: 0.9 tonnes

- Fresh grapes: 3 tonnes

- Fermented grapes 4.8 tonnes

- Dimensions L x W x H (mm): 2710 x 1400 x 1655

Merlin PLUS+ 1800 model

- Maximum weight:

- Whole cluster: 1.3 tonnes

- Fresh grapes: 4.5 tonnes

- Fermented grapes: 4.8 tonnes

- Dimensions L x W x H (mm): 3530 x 1400 x 1655

Merlin PLUS+ 2500 model

- Maximum weight:

- Whole cluster: 1.8 tonnes

- Fresh grapes: 6.3 tonnes

- Fermented grapes: 10 tonnes

- Dimensions L x W x H (mm): 3300 x 1750 x 2070

Merlin PLUS+ 3400 model

- Maximum weight:

- Whole cluster: 2.4 tonnes

- Fresh grapes: 8.5 tonnes

- Fermented grapes: 13.6 tonnes

- Dimensions L x W x H (mm): 4100 x 1750 x 2070

Merlin PLUS+ 4300 model

- Maximum weight:

- Whole cluster: 3.0 tonnes

- Fresh grapes: 10.8 tonnes

- Fermented grapes: 17.2 tonnes

- Dimensions L x W x H (mm): 4100 x 1750 x 2140

Merlin PLUS+ 5100 model

- Maximum weight:

- Whole cluster: 3.6 tonnes

- Fresh grapes: 12.8 tonnes

- Fermented grapes: 20.4 tonnes

- Dimensions L x W x H (mm): 4680 x 1750 x 2140

Willmes

Willmes is highly respected and valued in the global wine industry. They invented the pneumatic grape press, they continue manufacture very high quality ('golden standard' as they call it) equipment with features not found on other presses, and they export to 20 countries.

Here are some of the reasons why we choose Willmes:

- Established in 1918, they have over 100 years' experience of pressing technology

- Their engineers invented the pneumatic grape press (in 1951)

- Their press systems meet the highest requirements of quality and efficiency in grape processing, and produce high quality juice at low pressures

- The Willmes pressing principle, which consists of double membrane technology and vertical juice drains, and when compared with conventional systems, this results in 50% lower pressure pressing, <40 or 70% lower lees (depending on model), 25% or 30% more filling quantity (depending on Willmes model), and yields <90 or 95% at pressures of less than 0.8 bar (depending on model). Read our Willmes Pressing Principle blog for more information on these results.

- Their presses are easy to operate, easy to clean, and very low-maintenance

- Their presses also allow good pressing performance with small amounts of grapes

- All Willmes presses are manufactured in Germany

Blog

Read our Willmes Pressing Principle blog.

The Range

We supply the renowned Sigma and Merlin Willmes Presses.

Case Studies

There are at least 20 Willmes presses giving good service in UK wineries. Please call us to ask about our recent installations.

What we offer

In partnership with Willmes, we can offer you:

- Advice on the appropriate equipment for you - taking budget, space and desired throughput into consideration

- A comprehensive quotation outlining our recommended solution/s

- Full machine specifications with clear pricing

- Multi-skilled (Vigo) engineers to install and commission your equipment on site and provide training to you and your production operatives

- Comprehensive 12 month warranty, backed up by our team of Vigo engineers

- Maintenance & full technical backup and support from our mobile engineers

How can we help you?

If you're looking for a grape press for your winery, please give us a call on 01404 892 100 and we will be happy to discuss your requirements.

CAREFULLY SELECTED MANUFACTURERS

We have been supplying producers in the drink industry since 1984. We work with renowned manufacturers throughout Europe and in America to bring you robust and efficient production and processing equipment, backed up by our team of Vigo engineers. The manufacturer listed above is just one example. See our Manufacturers page for a list / more information on the manufacturers we are proud to work with.