German manufacturer Willmes GmbH are highly significant in the global wine industry. Not only have they been trading since 1918, they invented the pneumatic grape press, and are renowned for producing high quality (“golden standard” as they call it) wine presses. They credit their reputation with two key values: highest processing quality and German engineering skill. The results are, in their words, ‘press systems that meet the highest requirements of quality and efficiency in grape processing’.

We feel proud to be selling Willmes presses and it’s not solely due to their being well known in the industry, their recently released processing statistics speak for themselves and they are all as a result of the Willmes Pressing Principle blog:

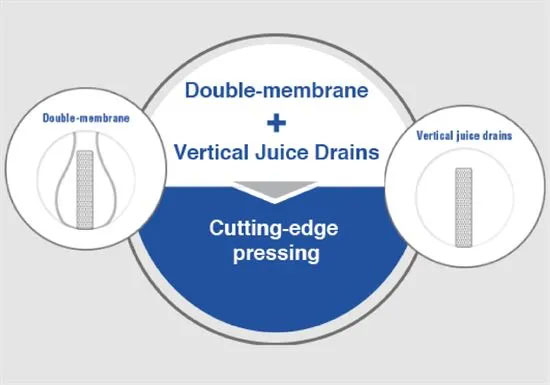

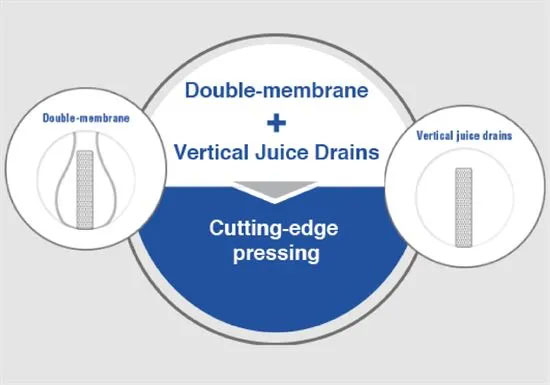

- 50% lower pressure: Willmes presses have a double-sided membrane, as opposed to a single-sided membrane, which brings a substantially larger (double) area of pressure application. This means less pressure expenditure and less compression of the material to be pressed at the same force — and this acts uniformly from all sides of the material to be pressed. In physics there is a relationship between pressure (P), force (F) and bearing surface (A). If the area of application doubles, pressure is halved at the same force [P=F/A].

- Up to 40% or 70% lower lees: This is all due to the lower pressure, fewer rotations and fewer pressing cycles. The gentle processing of grapes frequently result in 2% lees, therefore the juice yield and must quality are significantly increased. NB The percentages above are dependent on the Willmes model of press (Merlin press <40%; Sigma press <70%); and are when compared with conventional static presses, and even multiple times lower than in non-static presses.

- 25 or 30% more filling quantity: The design of the press body, the vertical filling and the vertical juice channels mean that the juice can flow directly into the filling channels without any need to rotate the body for optimal pre-juicing results. Vertical filling is more efficient and much gentler (for quality) than axial filling. NB Merlin 25%; Sigma 30%; when compared to conventional systems

- Yields up to 90 or 95% at pressures of less than 0.8 bar: The short juice paths through the vertical juice channels and the double area of pressure application result in impressive juice yields. The Merlin has perforated stainless steel juice channels, and the Sigma has Flexidrain® juice channels encased in Perfect-Flow mesh. If the press membrane is relieved of pressure, the material to be pressed falls together. All these features make the rotational effort for crumbling negligible and few pressing cycles are required. In addition, with the Sigma, the lateral pressure direction and their flexibility enables continual self-cleaning of the mesh tissue. Merlin <90%; Sigma <95%; when compared to conventional systems

All these design developments bring some benefits to the environment. The lower pressing power, a reduction of up to 50% of compressed air, and shorter pressing times mean better energy efficiency. The cleaning process is also faster and simpler.

Willmes pressing programs are designed to apply to all grades and types of grape harvest; you can also add your programs.

If you’d like to discuss Willmes presses, or our alternative Enoveneta range, please call us on 01404 892100.

Published Jun 3, 2019