Rotary lobe pumps are a form of positive displacement pump that use lobes rotating around parallel shafts to pump a product. They are highly versatile, pumping viscous liquids, fruit pulp, and free running liquids; they maintain a continuous flow; and are gentle on the product.

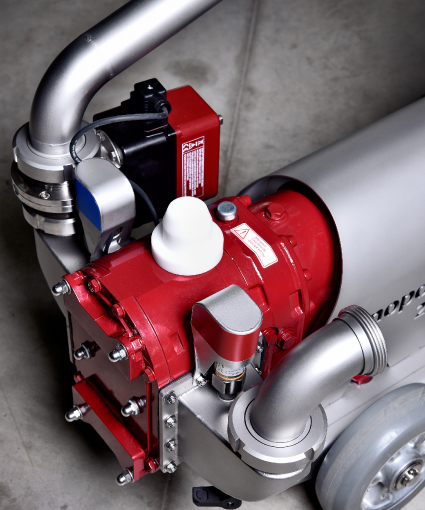

The Oenopompe is manufactured by PMV Vinicole, who have been supplying and serving wineries since 1835 and is a multifunctional pump specifically designed to provide the best pumping quality and for the demanding consitions of winery work.

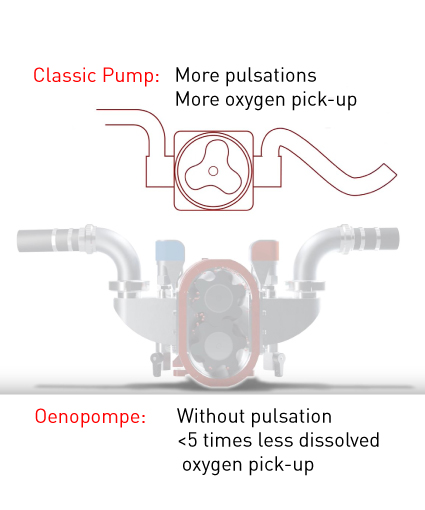

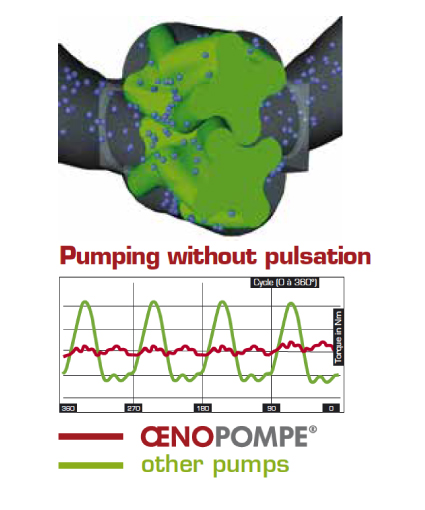

- Distinctive for it's innovative helical lobed rotary technology (see image & video)

- Wide range of applications, including pumping juices, wines, alcohol, lees, musts, de-stemmed grapes, high temperature juices, cleaning products

- Continous, smooth, guaranteed jolt-free flow

- Tested and accredited by the BNIC in Cognac

- Up to 5 times less dissolved oxygen during transfers - see Application for reference to article from La Vigne magazine in Features

- Includes speed variation, reverse direction, flow rate display, timer settings & servo control

- High frequency and long range remote control - includes flow rate display, speed variation, start/forward/reverse/stop, recharageable battery, battery charge indication, with handy hook (e.g., for hanging from lanyard)

- Models available:

- 15 to 130 Hl/h (1,500 to 13,000 lph): OENOPOMPE® 130

- 25 to 250 Hl/h (2,500 to 25,000 lph) : OENOPOMPE® 250

- 30 to 450 Hl/h (3,000 to 45,000 lph) : OENOPOMPE® 450

- 100 to 600 Hl/h (10,000 to 60,000 lph) : OENOPOMPE® 600

- Light, mobile, robust, 5 years breakdown cover*

- Easy draining, cleaning and maintenance

- LCD display - easy adjustment of settings; display of pumping parameters

- Options include: Touch screen, Oenoflux® electromagnetic flowmeter with accuracy of 99.7%, by-pass kit, automatic barrel filling and racking, adjustable regulation by pressure or temperature, external control, gravitaire freeflow with or without counting, run-dry sensor with adjustable timer, ATEX modifications, etc.

(*) Excludes wear parts; on board electrics 2 year warranty

Please call us on 01404 892 100 to discuss your pump requirements.

Please see the Pumps category in Catalogue for our full range of Pumps.

For hoses, please see our Hoses category; For hosetails and other fittings, please see our Fittings category. Please also see our Grape Crusher / Destemmers, Presses - Grape, &