Case Study Overview

Dreymans Cider produce a range of ciders from Discovery, Bramley, Cox and Russets. Deborah & Dave's pressing aims were ...

- Less labour intensive milling & pressing

- Equipment that absolutely right for them

We supplied, installed and commissioned a Voran automatic pressing/milling system.

Dreymans Cider was first produced in 2012, when partners Deborah Booth and Dave Shooter decided to turn their productive smallholding, with ancient orchard, into a business. They produce a range of single variety and blended variety ciders from Discovery, Bramley, Cox and Russets. As part of their Homegrown Hunnys enterprise, Deborah also produces various preserve from their cider, including cider jelly and spiced cider jam.

During the first 3 years of production, apples were pressed using a Voran 100P2 hydraulic press, but a less labour intensive way of milling and pressing was required.

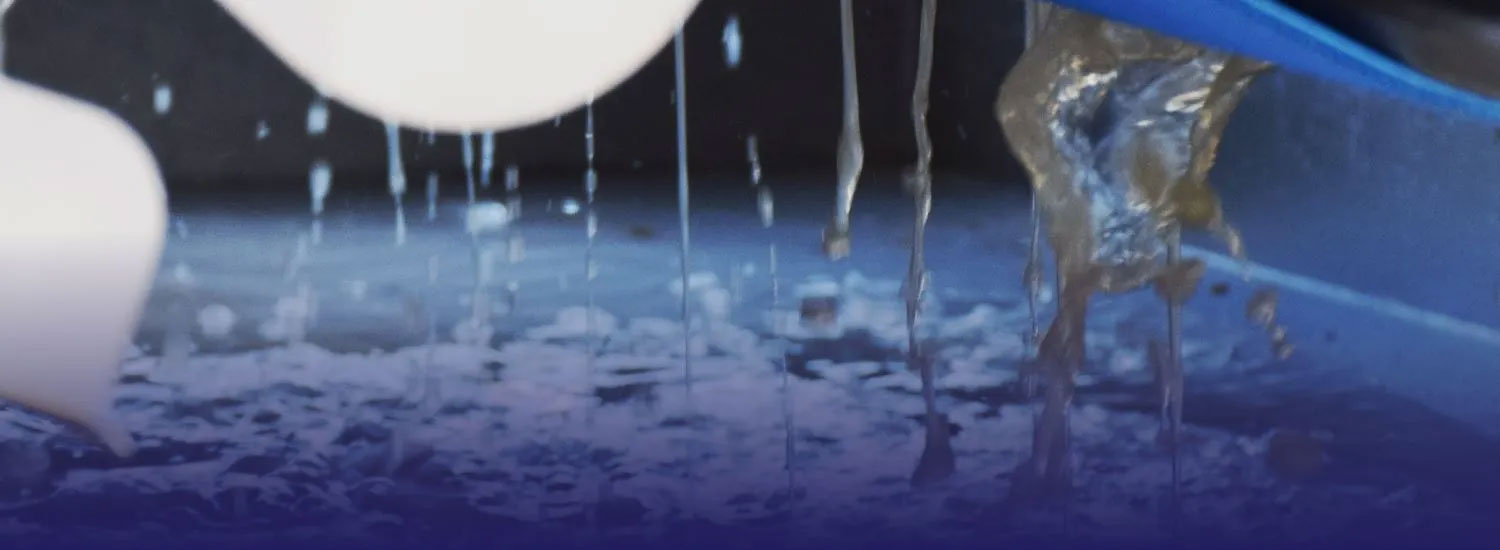

To enable a continuous, automatic pressing process, Vigo supplied, installed and commissioned a Voran SA wash mill with elevator and a Voran EBP350 belt press. Pulp is fed continuously from the mill into the belt of the press, where it is pressed against a series of steel rollers to extract the juice. Minimal labour and supervision are required.

Feedback

Vigo’s desire for correctness in choice of equipment mirrored our exacting requirements. The focused advice was very tailored to our needs.

The equipment was highly engineered and put many automotive products to shame. This coupled with the most expert installation and commissioning process allowed a seamless migration to our enhanced production status.

The high level automation of the production has allowed me to focus on product quality and to ensure a swift press from pick time line. You are without doubt our one-stop supplier moving forward. A wonderful experience and thank you.'

Deborah Booth, Dreyman Cider