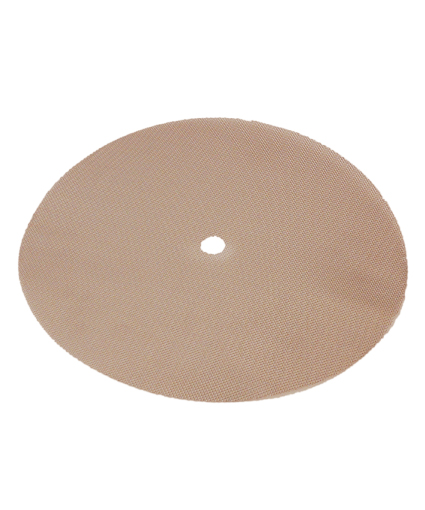

#Braumeister PLUS 10 litre

More

More

More

More

More

More

More

More

More

More

More

More

More

More

More

More

More

More

More

More

More

More

More

More

More

Qty: [itemQuantity]

£[itemPrice]

| Order Total | £[basketSummaryTotalSubTotalNet] |

|---|

Checkout Continue Shopping

This site uses cookies. By continuing your visit, you accept their use as set out in our Cookie Policy. OK