Application

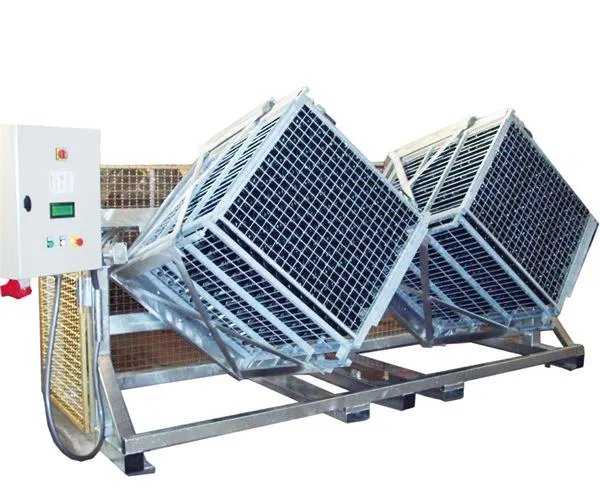

Automatic riddling machines consist of a motorised container which will turn the bottles (in the cage) from horizontal to vertical through angling and a series of rotations, driving the yeast deposits (lees) into the bottle necks. The machines can rotate the bottles in all directions at any angle and operate via programmes. The cage weight is spread evenly due to its cube shape, placing the centre of gravity in the middle. Low rotation speeds ensure that each bottle in the cage (504 capacity) gets exactly the same treatment.

Compared to manual riddling (turning each bottle by hand in a pupitre), automatic riddling machines machines not only automate the riddling process (saving a huge amount of labour), they bring the riddling time down from 4 to 6 weeks to around 7 to 10 days, and they promote a more effective form of riddling because of precision rotation and flexible angling (precision rotation is difficult with pupitres and the angle is predetermined by the pupitre's angled holes).

On completion the the bottles are neck-down ('sur pointes') and ready for disgorgement.