Application

- Suitable for both alkaline and/or acidic detergents

- are available as an optional extra

Operation:

A keg is placed on each station by the operator, and the integrated arrestor ensures that they are positioned correctly. The machine is started by dual push-bottom operation. Kegs are cleaned on the first station, and pressurised and filled on the second. For intensive cleaning of the basket, the detergent is flushed through the CO2 valve via counter flow method. The complete cleaning cycle is done with fresh water, caustic or acid from the integrated machine tank, and hot water, before the sterilising process takes place. A pulsed rinse ensures that the spear and the inner surface of the keg is completely cleaned. During cleaning and filling cycle, the operator is free to carry out other duties.

The operator slides the filled keg onto the waiting platform, transfers the cleaned keg to the filling station, and places the next keg to be cleaned on the cleaning station. On commencement of the next cycle, the operator slides the filled keg down the slider.

Features

Cleaning control devices

- Residual pressure check by pressure switch

- Empty message by electronic level switch

- Temperature control

Filling control devices

- Pressure control by pressure transducer

- Temperature control

CIP program with selection function for:

- Keg cleaning & filling

- Keg cleaning

- Beer pre and post run

- Emptying of filling head

- Steaming of filling head

- CIP cleaning from external CIP system or as agreed

YouTube

Click here to see the Twin II in use.

Malek Brautech

Malek Brautech GmbH are one of the leading specialists in keg treatment systems, hold several patents, and their international customers include Diageo Group and Efes Group. We are proud to be their UK agents.

Here are some of the reasons why we choose Malek for keg cleaning and filling systems:

Origins

Co-founder, Herbert Malek, brought 45 years of experience engineering and developing keg systems when he established Malek Brautech in 1992. Herbert began his professional career at one of the first engineering firms (Weigel) in Germany involved in the design and manufacture of keg systems, where he progressed to the Head of the Technical Department. Herbert went on to set up an engineering consultancy firm and it was during this phase that he developed a keg cleaning process which is still regarded as one of the best in the industry in terms of effectiveness.

Since it's inception, Malek Brautech has developed a strong portfolio of innovative keg cleaning and filling systems, aided by the passion and commitment of Herbert's son, Alexander. In 2014 Alexander took over the management of the company becoming CEO, safeguarding company as a family-owned OEM (original equipment manufacturer).

Design & Manufacture

Malek Brautech's expertise lies in the optimal cleaning and hygienic filling of kegs with low oxygen uptake. They design and manufacture keg cleaning and filling systems from individual machines to complete turnkey systems and hold several patents in the following areas:

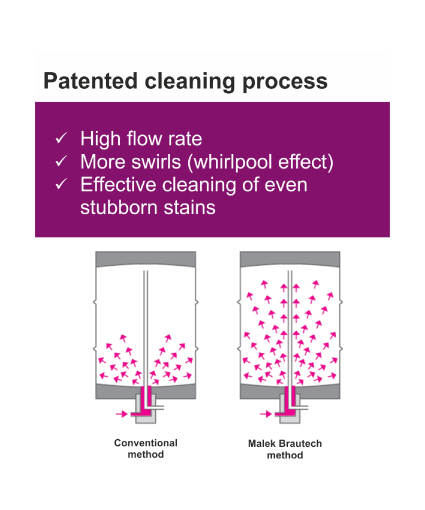

- Optimum performance keg cleaning - with high flow rate, more swirls (whirlpool effect), and effective cleaning even of stubborn stains

- Cold filling by temperature monitoring

- Condensate monitoring With the right care and maintenance, Malek Brautech kegging lines are designed to last over 30 years. All machines and systems are manufactured in their own production facility at Velbert. Malek uses high quality components from leading manufacturers and precision production methods, including CNC (computer numerical controlled) tooling, laser/water jet cutting systems, and WIG welding (the latter for frame structures and pipes).

Watch the Malek Brautech corporate video here

Reputation

Malek Brautech's international customers include Diageo Group/ Guinness Brewery (Dublin), Efes Group (Efes Pilsen), and König Brewery (Germany).

The Range

We supply Malek's full range of Keg Washers & Cleaners - some models are also suitable for mini-kegs & KeyKegs.

What we offer

We have been supplying, installing and commissioning Malek Brautech kegging systems for nearly 10 years. We can offer you:

- Advice on the appropriate line for you - taking budget, space and desired throughput, and labour, etc., into consideration

- Recommendation on kegging line layout and drawings

- Advice on power / water / compressed air requirements in your building

- Supply, installation and commissioning by our team of experienced, multi-skilled Vigo engineers

- Supply and installation (by our engineers) of all conveyoring and all the required controls to ensure your line works safely and efficiently

- Maintenance and full technical backup from our engineers

- Good stock of spare parts

Case Studies

The case studies below are only a few of the mulitiple kegging installations we've completed.

How can we help you?

If you're looking for kegging equipment, please give us a call on 01404 892 100 and we will be happy to discuss your requirements.

CAREFULLY SELECTED MANUFACTURERS

We have been supplying producers in the drink industry since 1984. We work with renowned manufacturers throughout Europe and in America to bring you robust and efficient production and processing equipment, backed up by our team of Vigo engineers. The manufacturer listed above is just one example. See our Manufacturers page for a list / more information on the manufacturers we are proud to work with.