Vigo is the UK agent for Bared. Bared have specialised in membrane technologies for the drinks industry for over 30 years and employ a team of highly skilled crossflow filtration specialists.

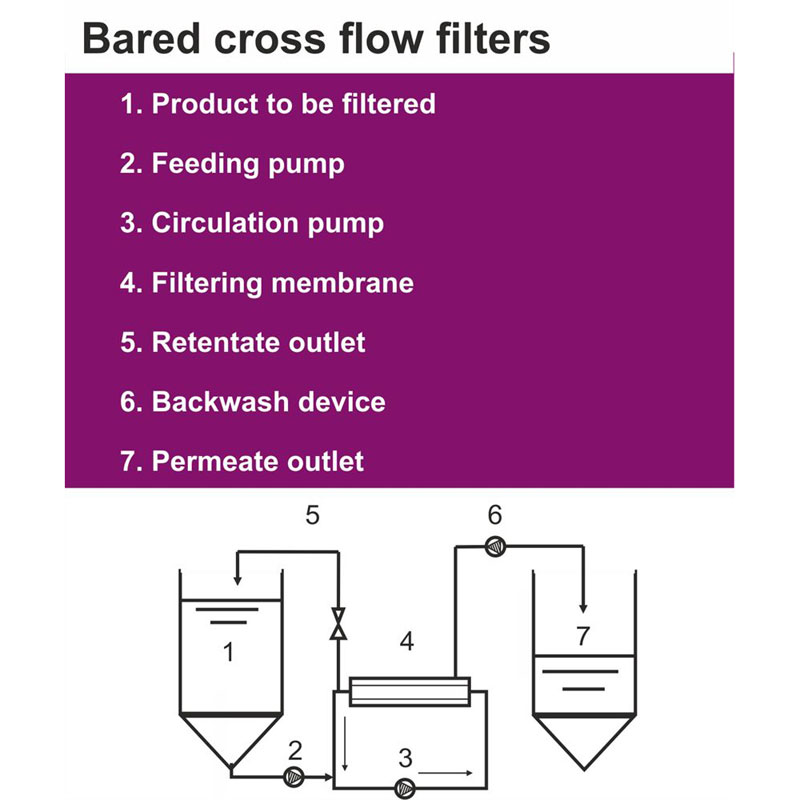

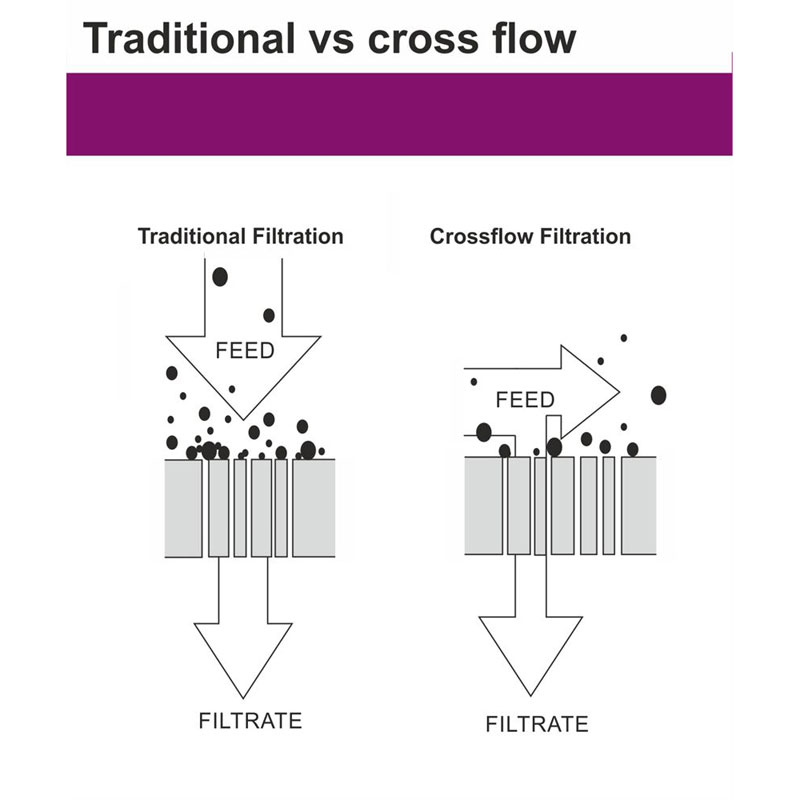

Bared's B range of cross flow filters are suitable for filtering wine, cider, and some other drinks. See the Features tab below for more information on cross flow filtration.

- Models available with flow rates from 700 up to 10,400 litres per hour - see Specification

- Double AISI 304 stainless steel pre-filter with stainless steel pleated cartridge

- Filtering modules with stainless steel housings and capillary polymeric (PP) membranes of 0.2 micron nominal pore size

- Centrifugal feeding pump, AISI 304 stainless steel

- Stainless steel recirculation pump, AISI 316 stainless steel

- Automatic back wash system operated by counter current pumping device

- Filtrate flow meter, observation glass, rates regulation valve, sample tap and pressure gauge

- Safety pressure switch device and working pressure gauges on loop section

- CIP system consists of double water pre-filter disposable polypropylene cartridge with pressure gauge and stainless steel buffer tank on wheels

- Control panel functions: recirculation pump, feeding pump, actuate valve, back-flushing settings, and thermometer/thermostatic device with alarm set point

- Stainless steel finishing: Internal surfaces 2B, polished; External surfaces, pipes & accessories, mirror polished or 2B

- AISI 304 stainless steel frame on wheels

- All pipework AISI 304 stainless steel

Installed & commissioned by our Engineers.

Please call us on 01404 892100 to discuss your filtration requirements.

See the 'Bared' tab (below) for customer Case Studies.

Please see Filters in Catalogue for our full range of filters.

Please see Filtration Media for our full range of filters cartridges, sheets, bags & socks.