Application

Kreyer temperature control equipment is widely are used for wine, beer and soft drink applications.

For wine

Temperature control can be a real asset to wineries in terms of optimising the consistency, the qualities, and the aromas characteristic of English and Welsh wines. Temperature can be controlled at product tank level; centrally via terminal or remotely; or via air conditioning for storage areas. These key temperature control functions can be met with Kreyer temperature control equipment:

- Cold settling of must and juices

- Fermentation control, including control by CO2 monitoring

- Cold stabilisation of wines

- Malolactic fermentation control (with heating option standard on most units)

- Long term control of product storage temperature

- Product chilling prior to carbonation

For beer

Brewers are looking to temperature control as a way of ensuring quality and consistency of their product. Temperature can be controlled at the room level, tank level, or product can be directly cooled or heated. This can ensure that wort is cooled at the rate you want, fermentation occurs at the rate that you want, and that your beer is stored in the conditions you want. Controlling temperature can also help your product retain some of the delicate flavours which can be easily lost. Chilling is also essential where beer is to be carbonated. These key temperature control functions can be met:

- Rapid cooling of wort

- Fermentation control, including control by CO2 monitoring

- Long term control of product storage temperature

- Product chilling prior to (and for effective) carbonation

For cider

Cider makers can use temperature control to optimise the consistency and quality of their product and chill it prior to carbonation. Temperature can be controlled at product tank level; centrally via terminal or remotely; or via air conditioning for storage areas. These functions can be met with Kreyer temperature control equipment:

- Fermentation control

- Long term control of product storage temperature

- these units can be used to chill the product prior to (and for effective) carbonation. *Kreyer temperature control equipment is applicable to other drink applications, including spirits & mead; please contact us on 01404 892100 to discuss your requirements.

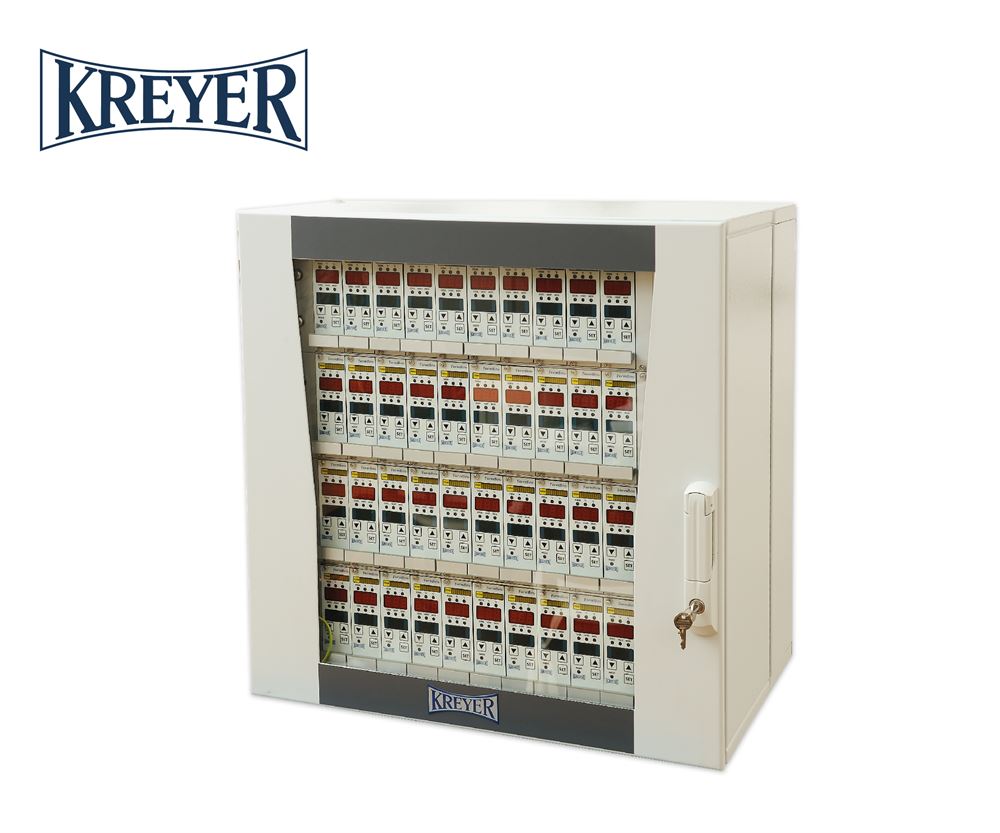

Quantor (Kreyer)

WTG Quantor (incorporating Kreyer) manufacture technologically advanced cooling and temperature regulation systems for drink producers.

Their range includes equipment for refrigeration and temperature control at all stages of drink production, either at tank level, room level or through direct cooling or heating. We choose Quantor for the following reasons:

- They have 40 years specialist experience supplying temperature control technology to wineries across the world - their range now incorporates other drink sectors, including beer, cider, spirits and fruit juices

- Their cooling and temperature control systems have a well-earned, proven reputation in wineries throughout the world - they now export to more than 80 countries across the world in all 5 continents

- They have developed innovative systems for temperature regulation, CO2 monitoring, micro/macro oxygenation, and room temperature control

- They manufacture in-house

Company Development

The Kreyer brand was founded in 1970 in Villefranche sur Saône, France - the centre of the Beaujolais wine production area. In 1998 the company changed ownership and was incorporated by Wine Technology GmbH (WTG), an Austrian, American & German partnership, and since then headquarters have been located in the triangle of Germany, France & Luxembourg, in the heart of the Mosel winegrowing region. Further company expansion led to the development of larger production facilities. The company has since expanded and changed its name to WTG-Quantor GmbH. WTG-Quantor is now represented in all major wine-growing countries worldwide, incorporating over 80 countries, including Chile, South Africa and Australia.

Functions

Quantor's equipment range covers the following functions:

- Cold settling of must and juices

- Fermentation control, including control by CO2 monitoring

- Malolactic fermentation control (with heating option standard on most units)

- Micro/macro oxygenation

- Rapid cooling of wort

- Long term control of product storage temperature

- Product chilling prior to carbonation

- Cold stabilisation

The Range

The range includes Chiller Units, Heating & Chiller Units, Temperature Control Systems, & Air Conditioning Units - please see Temperature Control & Chilling.

What we offer...

We have over 10 years' experience providing and customising Kreyer temperature control solutions, from individual machines to complete computerised systems. We can offer you:

- Advice on the appropriate equipment for you - taking budget, space and desired throughput, and labour, etc., into consideration

- A comprehensive quotation outlining recommended solution/s and clear specifications

- We can include Speidel stainless steel tanks (as listed in Tanks) with heating/cooling jackets, which work in conjunction with Kreyer systems

- Supply, installation (including the construction of ringmains) and commissioning by our team of experienced, multi-skilled Vigo engineers

- Comprehensive 12 month warranty, backed up by our team of Vigo engineers

- Maintenance & full technical backup and support from our mobile engineers

- Spare parts

Case Studies

The Case Studies below represent a few of the multiple Kreyer temperature control systems we have installed:

How can we help you?

If you're looking for chilling or temperature control solutions, please give us a call on 01404 892 100 and we will be happy to discuss your requirements.

CAREFULLY SELECTED MANUFACTURERS

We have been supplying producers in the drink industry since 1984. We work with renowned manufacturers throughout Europe and in America to bring you robust and efficient production and processing equipment, backed up by our team of Vigo engineers. The manufacturer listed above is just one example. See our Manufacturers page for a list / more information on the manufacturers we are proud to work with.