Application

- Suitable for both alkaline or acidic detergents

The Malek Twin 2000 keg cleaner is designed and manufactured by Malek Brautech GmbH, who specialise in the field of keg filling and keg cleaning systems. The Twin 2000 is a compact semi automatic machine for cleaning kegs, which uses the same patented cleaning process as the Twin II semi-automatic keg cleaner & filler, but has double the output per hour It is suitable for cleaning using alkaline or acidic detergents.

Installed & commissioned by our Engineers.

Please call us on 01404 892100 to discuss your kegging requirements.

See the 'Malek' tab (below) for customer Case Studies.

See Keg Fillers & Washers in Catalogue for our full range of keg fillers & washers

Cleaning control devices:

Malek Brautech GmbH are one of the leading specialists in keg treatment systems, hold several patents, and their international customers include Diageo Group and Efes Group. We are proud to be their UK agents.

Here are some of the reasons why we choose Malek for keg cleaning and filling systems:

Origins

Co-founder, Herbert Malek, brought 45 years of experience engineering and developing keg systems when he established Malek Brautech in 1992. Herbert began his professional career at one of the first engineering firms (Weigel) in Germany involved in the design and manufacture of keg systems, where he progressed to the Head of the Technical Department. Herbert went on to set up an engineering consultancy firm and it was during this phase that he developed a keg cleaning process which is still regarded as one of the best in the industry in terms of effectiveness.

Since it's inception, Malek Brautech has developed a strong portfolio of innovative keg cleaning and filling systems, aided by the passion and commitment of Herbert's son, Alexander. In 2014 Alexander took over the management of the company becoming CEO, safeguarding company as a family-owned OEM (original equipment manufacturer).

Design & Manufacture

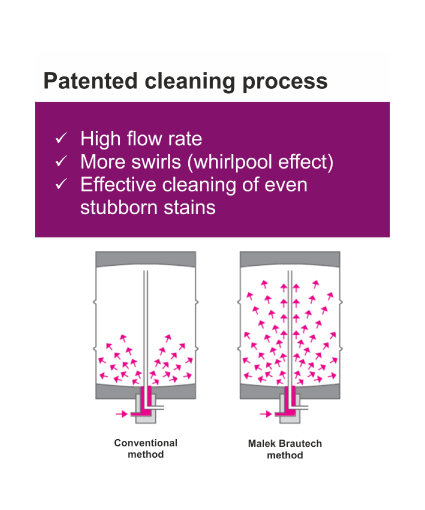

Malek Brautech's expertise lies in the optimal cleaning and hygienic filling of kegs with low oxygen uptake. They design and manufacture keg cleaning and filling systems from individual machines to complete turnkey systems and hold several patents in the following areas:

Watch the Malek Brautech corporate video here

Reputation

Malek Brautech's international customers include Diageo Group/ Guinness Brewery (Dublin), Efes Group (Efes Pilsen), and König Brewery (Germany).

The Range

We supply Malek's full range of Keg Washers & Cleaners - some models are also suitable for mini-kegs & KeyKegs.

What we offer

We have been supplying, installing and commissioning Malek Brautech kegging systems for nearly 10 years. We can offer you:

Case Studies

The case studies below are only a few of the mulitiple kegging installations we've completed.

How can we help you?

If you're looking for kegging equipment, please give us a call on 01404 892 100 and we will be happy to discuss your requirements.

CAREFULLY SELECTED MANUFACTURERS

We have been supplying producers in the drink industry since 1984. We work with renowned manufacturers throughout Europe and in America to bring you robust and efficient production and processing equipment, backed up by our team of Vigo engineers. The manufacturer listed above is just one example. See our Manufacturers page for a list / more information on the manufacturers we are proud to work with.