Application

Here are some of the reasons why craft breweries are moving to cans:

- They help protect beer from light and oxygen

- They retain fresh hop flavours

- Modern cans are lined with a polymer lining so that the beer doesn't touch any metal

Cans also have other shared benefits for a wide range of beverages:

- They are highly portable

- They are welcome in places where bottles are not

- They can be crushed down when empty and are easily recyclable

- Compared to bottles, they are space-saving, lighter and they won't smash

- The unit cost of a can is cheaper than that of a bottle, label and cap

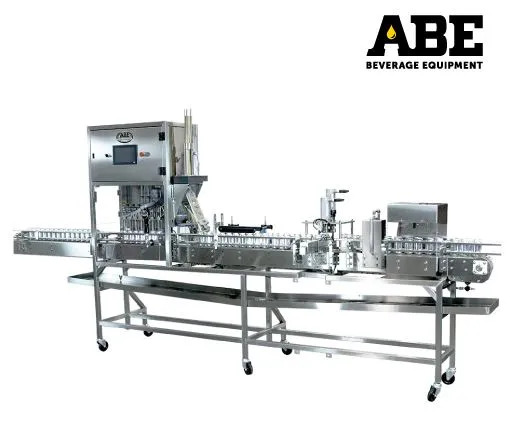

The canning process using the LinCan includes:

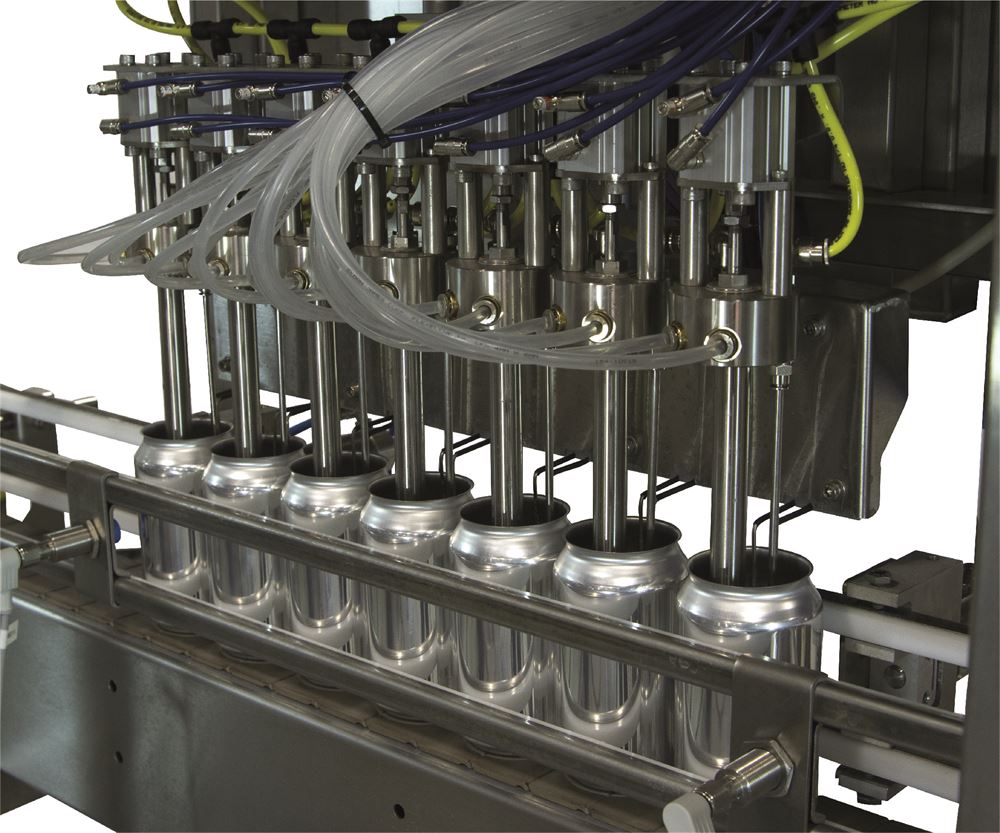

- Filling head process:

- Oxygen purge

- Fill

- CO2 micro-burst for reducing dissolved oxygen pickup

- Lid applicator gasses to reduce oxygen pickup

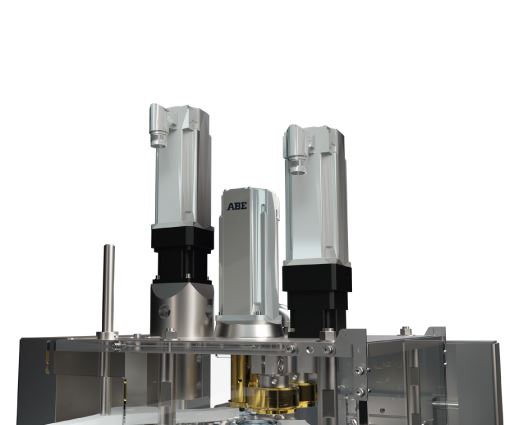

- Secure lid-tamping and seaming process, which includes seamer monitoring (see features)

- Can rinsing and drying